EV Charger Temperature Management Blind Spots: Common Oversights, Detection, and Effective Solutions

Does your EV charger slow down, shut off, or feel excessively hot during summer charging sessions or high-load operation? From real installer and operator feedback, many “efficiency drops” or unexpected interruptions trace back to temperature management oversights – not the charger hardware itself. In variable climates like the Netherlands (rainy winters, warmer summers), poor thermal handling can lead to reduced performance or safety risks. This article breaks down common blind spots from actual project experiences to help you identify and fix them.

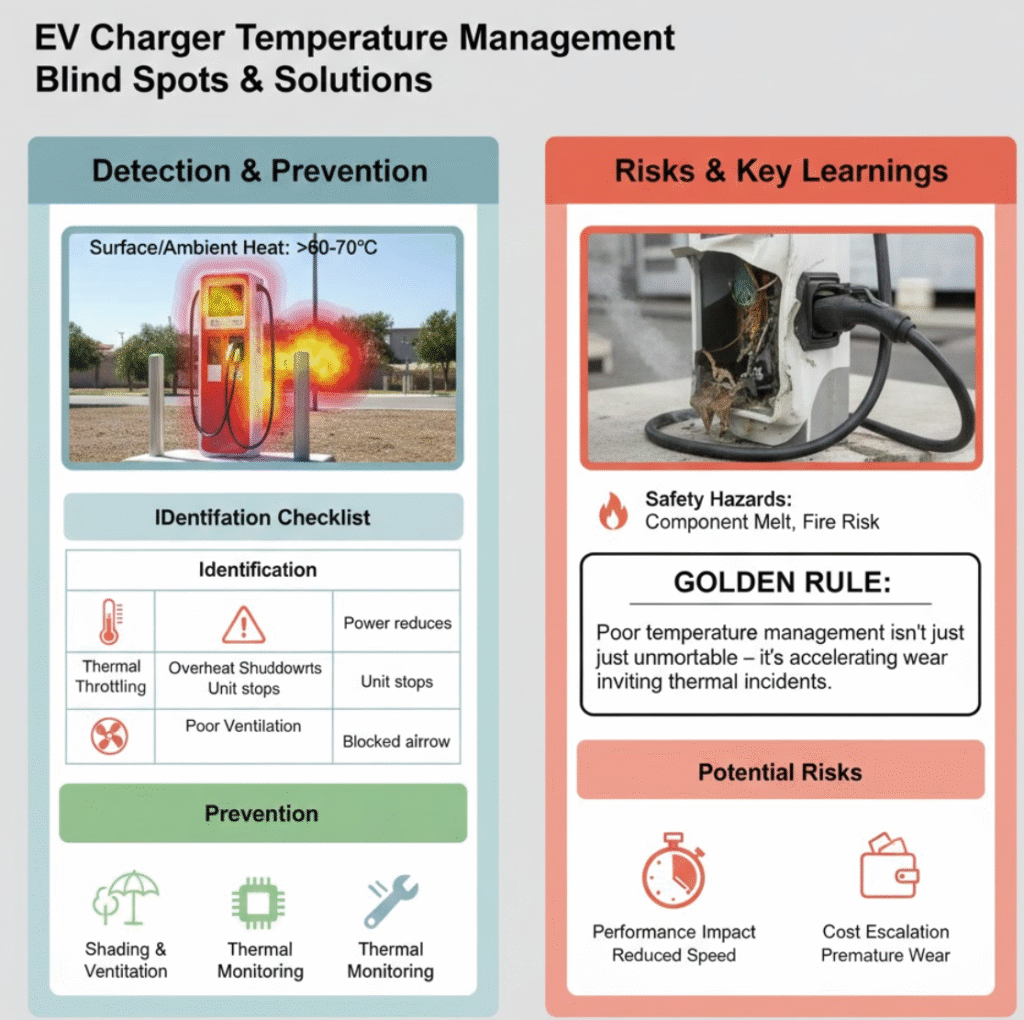

What Are EV Charger Temperature Management Blind Spots? Temperature management blind spots occur when the charger’s thermal design, installation, or monitoring fails to handle heat buildup from continuous high-power charging, poor ventilation, or environmental factors. IEC 61851 requires over-temperature protection (thermal sensors, automatic power reduction), but oversights in deployment often bypass effective cooling. Client example: “In hot weather, charging power halves after 20 minutes” – typically due to undetected heat accumulation in the unit.

How to Detect Temperature Management Issues?

On-site indicators:

- Surface/ambient heat: Charger body >60–70°C during operation (use thermal imaging for hotspots).

- Performance drop: Charging slows or pauses without error codes (thermal throttling).

- Warning signs: Overheat indicators, reduced output in warm weather, or frequent restarts.

Table: Temperature Management Issue Detection Checklist

| Issue Indicator | What to Check | Common Client Feedback |

|---|---|---|

| Excessive Surface Heat | Body/cables >60–70°C (thermal camera) | “Charger feels burning hot in summer” |

| Thermal Throttling | Power reduces after sustained load | “Charging speed drops halfway through” |

| Overheat Shutdowns | Unit stops without overload code | “Stops in warm weather, restarts when cooled” |

| Poor Ventilation Signs | Debris/blocked airflow around unit | “Outdoor charger overheats quickly” |

How to Address and Prevent Temperature Blind Spots?

Adhere to IEC 61851 (thermal protection mandatory in Modes 3/4) and EU best practices:

- Ventilation priority: Ensure >50 cm clearance; install in shaded, well-ventilated areas (critical for NL outdoor sites).

- Thermal monitoring: Use built-in sensors for auto power reduction at high temps; add external monitoring if needed.

- Site planning: Avoid direct sun exposure; use weatherproof covers; schedule high-load charging during cooler hours.

- Regular checks: Thermal imaging every 6 months; test full-load in simulated heat.

Potential Risks of Temperature Blind Spots

Overlooking these can cause:

- Safety hazards: Overheating leads to component stress, melted parts, or fire risk (thermal runaway in extreme cases; EU reports link heat to 15–20% failures).

- Performance impact: Reduced charging speed, user dissatisfaction, lower utilization.

- Cost escalation: Premature wear, frequent service calls, warranty issues.

FAQ

- Q: Is some heat normal during charging?

- A: Yes, up to 50–60°C is acceptable per IEC, but sustained >70°C signals a problem.

- Q: Best for Netherlands outdoor chargers?

- A: Shade + ventilation; monitor in summer peaks to prevent throttling.

Share your temperature-related challenges for tailored insights with POWERIS TEAM.